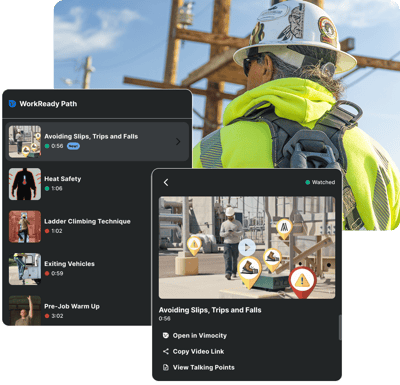

From Groundman to Founder: When Frontline Experience Meets Entrepreneurial Hustle

WorkReady Podcast Episode 20

-

Speakers

Felipe Carrillo | Wye Delta

Dr. Kevin Rindal | Vimocity -

View The Transcript

What happens when frontline experience meets entrepreneurial hustle?

Guys make money out there in the field, so they want to look good. They wanna feel good, and they want the best, and I don't see why not.

Today we talk to Wye Delta's, Felipe Carrillo about his journey from groundman to founder, and why the most effective safety innovations are the ones that workers actually want to use.Without your body, you're not making money. And without making money, you're gonna struggle. It doesn't have to be Wye Delta. Because you can wear any other branches. Wear something safe.

This is the WorkReady Podcast.Today's guest is an entrepreneur who's taken lessons from the job site and turned them into a business designed for people who work in demanding environments every day. Felipe, it's so great to have you on this call.

Thanks so much. And you know, my first exposure.

Wye Delta was at the International Line Rodeo, and you had like the hottest booth in the whole place.I mean, there was a little lineup all the way out the door and people were, uh, supporting your glasses everywhere. And it, it's pretty cool to see a product that's, you know, ultimately a safety product, but people wanna wear it because it just looks good and it, it meets their needs and it's high performing.So, I'm so excited to talk about this, uh, as we get into our conversation.

Yeah, absolutely.

One of the things that I've always learned is, um, always put pride in the work that you do. So when I design my booth, I like to make it stand out, you know, let people know that we put pride in the work that we're doing here.For sure. And so you started out as a groundman, and tell us a little bit about your experience once you got your feet wet and you started to actually do the work. What was, what was it that like? Uh, it was pretty nerve wracking, especially the first thing I did was climb lattice towers. I believe they were 300 feet tall, uh, 500 KV volts, and it was pretty exciting.

I was up in the air every day. We're climbing them. We don't, we didn't use helicopters, so we were climbing up and down these towers. And at first I thought, you know, I'm probably gonna just climb some poles and, and do your regular work. But no, we were doing transmission jobs and um, I never thought I'd be 300 feet in the air, you know, so it was very exciting.

Um, I knew from that moment that definitely becoming a lineman was something that I wanted to do. Unfortunately, due to my back injuries, that was a, a big stop, a dead end to me. But I continued on as a groundman, um, and. That's where basically I ended at things. Yeah. Tell us more about your back injury.

'cause uh, once you became a groundman, that was something that flared back up again and it really impacted, uh, your ability to continue to do the physical work. Yeah, so shortly after I graduated, um, line school, I, um, I had a pinched nerve. It was something that I was willing to put up with. And I didn't take a lot of painkillers 'cause I knew I was gonna be doing that forever.

So it affected me because every day that I was out in, in these towers, I had pain. I had pain in my back every day. And I like to play soccer by the way, and I'm very athletic. Um, so I would go work and then if I play soccer, my body would start leaning to the side and I would told myself, I can't play soccer no more, or I can't work.

So obviously, you know, I chose work. And, uh, every day I have this pain every day. So, uh, I remember trying to climb as a, as a groundman out of local 47, and I just, as soon as I climbed my bat, started icking. And I said, you know what? I'm just gonna stay as a groundman for now. I didn't play sports or do any physical activities for five years, and my back got a lot better, which I was very happy.

And then that's when I went ahead and tried climbing again. Again, it happened. I pinched that sciatic nerve once more. And uh, at this point I was married and had kids, so I had to make a tough decision and I already had the company Wye Delta, so I said, you know what? I'm gonna stay as a Groundman, and then later just focus on WYE Delta.

Yeah. And this is a WorkReady podcast. We, we talk about being work ready and, you know, physically being, um, you know, maintaining your, your musculoskeletal health so you can, uh, continue to work. But there are situations like this where, you know, the, the back can be an ongoing problem. What are some of the things that you learned along the way about your own body and things that you could do to help, um, mitigate that pain?

So I was watching your podcast with Scott, you know, from poll, uh, post, was it Poll? Poll Cast, yeah. Podcast or Yeah, podcast. And he said that, uh, when you're young, anything is possible. You feel invincible, you'll pick up heavy materials, you'll. You know, you won't think about it twice doing something that you're not supposed to.

And one of the things that I've learned is that it catches on. So taking care of your body is very critical. It's important. Um, an injury like myself can stop you from, uh, accomplishing that career that you've been dreaming for it. So when we, when we go to work. We are stretching every morning. Every morning.

We have a 15 to 30 minute stretch for the most part. I'll be honest, I did it myself. I just stood around and did something like this and I was like, ah, whatever. Like, let's go to work. I thought I was ready for work, but I was mentally ready, but I wasn't physically ready. I should have taken like stretching a little bit more serious.

Um, and then you, you come to realize. How important it was once it happened, so people don't think, oh, I'm, I'll be fine until you're up on the pole and you pull a muscle or you get a cramp and then you're like, damn, I shoulda stretched, and it's a little too late for that. Right. So it's a, it's an experience.

Well, the one thing that I so admire about you, fbe, is that, you know, you took a situation where I think you had to have that reality check of, man, maybe this isn't the, the best career for my body. I, I do have WYE Delta as a backup plan. And so it just allowed you to, to be able to make that transition.

But let's go all the way back to when this even became like, you know, the infancy stages of a thought process of, man, this industry needs. Better safety glasses, like how did you come to that conclusion? My buddy and I, the co-founder Albert Aria, he's actually a lineman out of Local 47. Him and I were ground men at the, uh, local for, for local 47.

And I remember we worked for the same company. We were making a lot of money. We were working 105 hours, a hundred hours a week. And again, I was single. I didn't have a house, I didn't have any type of write-offs or something that I can say, lemme get away from some of these taxes. Right? So my buddy said we should just open up an LLC.

Everybody says that, but nobody really knows. How deep can you get? Right? So we opened up an LLC and I like the name WYE Delta. 'cause when we were in school they taught us about the electrical systems or transformer connections. And I told 'em we should just name it WYE Delta and do safety glasses. 'cause one of the things that I noticed is.

Everybody brings their own glasses to work, but on site. So at the time, I used to wear my Oakley Holbrooks and uh, when we were on the job sites, our, our field supervisors would show up and he'd be like, Hey, you have to wear the safety glasses that we provide. So he'd give us this plastic bag with these cheap glasses, and we'd be like, all right, whatever, you know, we'll put 'em on.

But then when he took off, we'd all take them off and put our glasses back on, you know, and it, and it was like one of those things that. Oh, nothing's gonna happen. I've been in the field for five years. I've never had an eye injury, so it's not gonna happen. And it's until you see it that you're like, well, maybe I should wear my, my safety glasses.

And so then I told my buddy, let's just do something fashionable, something comfortable, and that represents the industry that we're in. And that's what we did. And we named it WYE Delta. And for our listeners who don't know what WYE Delta to means, can you go, uh, elaborate a little bit more in, in terms of how that relates to the electric profession?

Of course. So when we were in school at NLC, we pretty much learned a little bit about everything and. How they taught us WYE Delta was Transformers connections. So you have your primaries and your secondaries, and there's four ways of doing these connections. You got your Delta Delta system, you got your Delta Y system, you got your YY system, and then you got your WYE Delta system.

And to me, WYE Delta just stood out and I really, I really like it. They're basically just transformer connections or. Uh, ways that electricity, electricity is distributed, Y is very, uh, common. It carries more, uh, it carries more different voltage, and delta is more like for like bigger industries, higher, uh, uh, voltages and whatnot.

So it, and also y is a grounded system and Delta is not. So it's, it's, um, it gets deeper than that. But pretty much that's how, that's how it works. It's a cool logo. I, I really like the, so appreciate it. Yeah. I love it. Yeah. Uh, one of the things that, as we were preparing for this, you talked about, uh, an inspiration from an entrepreneurial perspective was Mark Groves at NLC, and he talked about like the OX Block.

And Mark has been a guest on this podcast as well. Can you share a little bit more about that? Yeah, so we were in, in school and someone had mentioned that Mark Grove came up with the ox blocks and they were showing us the functions and how it worked. And they said this is something that changed, uh, the game and the industry.

So one of the things that I, that stuck to me was like this guy. Went out in the field. He was a lineman. I think he graduated in 1996, and then he became a lineman. He was in alignment for 15 years. And then he came up with a product that solved a, you know, a problem. So one of the things that I, that stuck with me is like, I wanna do something like that.

You know, I want to go out in the field, I wanna use tools, I wanna use equipment. Excuse me. I wanna know how I can better that, how I can make something that says, Hey, this product will help you a lot more in the field. It's, and I got into the safety glasses 'cause I, I wore a lot of glasses at the time and I figured, figured might as well, you know, do that part of the safety industry.

What about the glasses that your safety, uh, leader handed you in the little plastic bag and you put 'em on? Like, what w what were the things, the attributes of those glasses that caused people on the team to say, oh man, I'm just gonna wear these for compliance, but I'm gonna go back to my Oakley as, as soon as I get back up to work.

So one of the things that I didn't like is that they were too close to your face. So when I was sweating, the, the sweat would come down the lens or they're just uncomfortable. They'll start pinching your ears and your nose like it's. They're plastic, they're sharp. So overall, they're very uncomfortable and they look, they're not the fashion, you know?

So, uh, you gotta think about it, guys make money out there in the field. So they want to look good, they wanna feel good, and they want the best. And I don't see why not. You know, it, our jobs is very important and critical. So if you think about it, I, I always tell my customers, you're spending about 120 to $200 for FR clothing.

One person, but you're spending $5 on glasses and they're not wearing it. You know, it's a, it's a liability just waiting to happen. Um, I was like, if you buy them some good glasses, right, they're gonna wear them and they're gonna last you a lot longer than these $5 glasses at the end of the day. I was like, I've seen it firsthand.

We throw 'em away, they end up in the trash. The, the field supervisor came by at least twice a month and he gave us all a pair every single time. And I was like, and that's going to the trash. So why not just spend a little bit more money and have the guys actually wear the product? I personally do a lot of snow skiing and uh, cycling and there's nothing more frustrating than fogged up goggles or goggles.

Yeah. Or sunglasses. It's a safety concern 'cause you can't see what's it in front of you. And so I would imagine in every athlete knows this is that. Good vision and good eyewear actually is a competitive advantage because not only does it make you, um, safer, but it, it can actually enhance your performance.

Because if you use like polarized lenses versus just, you know, a standard lens, you're gonna be able to see in greater detail, how do you see like the higher quality safety glasses actually being able to potentially enhance safety. So I'm gonna show you here something.

So when it comes to, um, the anti-fog problem we were talking about, um, we have an anti-fog lens, but at the same time, we have an adjustable nose piece on the inside of our glasses. So when you pinch that nose piece, your glasses lift up a little bit. And so when you're wearing a, let's just say a gator mask and you're breathing and all that, um, uh, air comes out and it fogs your lenses.

Well, if you lift it, if you pinch this nose piece here, your glasses lift up a little bit given room for that air to, to escape and not interfere with your lenses. So also, everyone has a different nose bridge. So we like to add adjustable nose bridge to almost all our glasses for a better fit and a, and a comfort fit.

And you'd mentioned as well that, uh, the, the arms that come out, you know, that can be really annoying for some people or if they're wearing a hard hat or Yeah. You know, a hat that can impact how the glasses fit. Uh, can you talk a little bit more about some of your thought process of how to optimize that?

Of course. So we go through a lot of trial and error, right? When we, when I first started the company, I chose. Three different types of glasses. And then I added these right here, which are the, our second most popular, it's called the full vis. When I first came up with this product, we had a straight arm.

It kind of looked like, so like this. And when people would wear them and they'd put their hat on or their hard hat, the glasses would lift. And then, so there, it'll look like this. And it was a lot of, we got a lot of emails, a lot of feedback of customers saying, all the glasses lift up. So we went ahead and redesigned it, right?

So we take customers, uh, feedback very seriously. So we redesigned it. We just added a little curvature, just like almost every other glasses and all, every time we have a. A problem with our, our safety product, we like to redesign and reinvent. So we're actually going through redesigning the vis, which is this one here.

So currently, um, we are, we're, we're having issues with the Hinches here on our glasses and we've got a lot of feedback on it. And what we're doing is we're reinforcing it and we're redesigning, and I think that's what makes us better. That's what makes us, uh, move forward in the industry to say. Hey, we're not just gonna say, oh, well you already paid for it.

You know, we're gonna be, we're gonna take that feedback back and we're gonna redesign this entire mold. And that's what we do. That's how we better our product and make sure the guys are happy and they are actually gonna wear that product. The safety glasses. And for the, the audience, I think it's important to.

Also talk about the lens and the safety features of it. Like why should people be wearing, uh, certified, uh, safety glasses when it comes to protecting their eyes? What's the, the purpose of the side shields and how should people be thinking about, uh, selection when it comes to glasses? Well, it's very important to have a C 87 plus rated lens because if you have, let's just say you're wearing some Ray bands or Oakleys that are not certified, that's actually glass.

And if you get an impact into the eye and it shatters, all that glass is gonna go into your eye, potentially losing sight. So it's very important to have something that's a, a lens. So a C 87 plus lens needs to be at least minimum of two point. 2.33 millimeters thick in order for it not to break, and it has to be polycarbonate.

Um, so it's very important to have that safety future. Otherwise you're definitely risking your, your eyesight for the near future. Uh, we have guys that have contacted us and said, Hey man, I'm really happy I was wearing your glasses. In fact, uh, last month, a guy came into arc flash. It was 13 KV volts and his entire phase was burnt.

He was wearing these glasses and you can see that the glasses were a little bit burnt, but his eyes were completely intact and he emailed us saying that he was very grateful to have been wearing our glasses. And I say, Hey. Let's use that as a testimony, you know, um, it doesn't matter if it's WYE Delta or another brand, just wear your safety product because this guy's back on the field.

He just went back on the field like a, a few weeks ago, and if he wasn't wearing that safety glasses, then God knows if he would've had that eyesight. And it's very important and have that. That's, yeah, that's an incredible story because I think it goes back to the fact it's kinda like, um, fr clothing, fr clothing.

You look at it 15 years ago and it was not comfortable to wear. And uh, you know, I have great partnership with Dragon Wear. They send me some of their shirts. I go hiking and running. I actually prefer to wear their, their clothing when I, when I go out and run. 'cause it's so comfortable. And so I think it goes back to the fact that if you make performance gear, because you guys are industrial athletes, if you wear and create gear that can meet the demands of the job and it's meant for performance, people are gonna wear it more often and they're gonna be safe.

And for that guy, I mean. Literally he's able to see today because he was wearing the right type of glasses. I mean, what would've happened if he, like you, was wearing Oakleys? Because he is like, I, I want, you know, better looking eyewear. I want, uh, something that performs better, but it, it isn't rated, it's not, uh, you know, polycarbon so that it, uh, protects your eyes well, potentially if, if.

Glasses that he was wearing weren't, uh, C 87 plus the frame could have melted onto his face and the glass, uh, could have shattered or, you know, um, they could have fallen off. And if he didn't have that side protection as well, he would've, it would've gotten really close to his eyeballs. Um, again, it's very important to wear the product that is, is given to you.

So, uh, I've, I've seen again, in firsthand a guy was. Stripping wire, and he didn't like the gloves that were given to us and I, nobody did. There were these plain white gloves and he took 'em off and he was stripping wire and he cut half his palm right here. So, um, you know, the company goes back and says, you gotta wear the gloves.

And then the safety manager said, you know what, let's just buy them some good ones so that they can wear them. And then it's one of those things, why wait for it to happen? If you know, it's a, it's a problem right now, ask, you can ask any field supervisor every time they go out on the field, are they wearing the safety glasses or gloves that you are providing?

And if the answer is no, then they have a problem. They're waiting for something to happen. And I always tell 'em like, get, let's get ahead of the game and solve that problem. There's no, you can't put a price on safety. Absolutely. And you think about the price differential between a $5 pair of glasses that are gonna do the job versus, you know, maybe you spend 120 bucks for, for glasses, like that's so much cheaper than a hospital visit and loss vision.

Yeah. A hundred percent more cheaper. And then you, one of the things that customers forget to think about is, or take into consideration is that buying something like this will last you a lot longer than the ones that go straight into the trash. It's one of those things that, that's just how we are in the field, you know?

And I, I believe that if lineman want a specific tool or a specific, uh, piece of equipment, then the company should make that investment. I go to a lot of trade shows. I see new product coming out, and that's why we do like the utility expo. We do the Kansas City Lineman Rodeo. It's so that companies can come and say, Hey, there's a new tool out there that.

Can help better our jobs. Um, and that's just one of those things that companies needs to, they start, you know, hopping on board and realizing that it's very important to, to invest in their employees rather than having liabilities. Yeah. And you briefly mentioned the side shield. Can you, uh, talk a little bit more about why that's so important and some of the ways that you've been able to innovate in that area?

Yeah, so the side shield, uh, I'll show you here, um, how that works.

So this is kind of one of those things for like, on the job and off the, and off the job, right? So when you're at work, uh, OSHA requires C 87 plus. As you can see, these glasses are not like, like these, uh, wrap around, right? See how these wrap around. The bottom ones qualify for CD seven plus. These don't, so we have to add that side shield, like so you slide it on there and now you got that side protection, right, because, oh, uh, we work with different types of materials, equipment, and something can launch from the side.

And if you're not wearing the sideshow, then your, your eye is still in danger and potentially can, it's a hazard. So that's why the side shield's there. And I really like the fact that it can be removed because if you wanna wear 'em outside of work, um, it's a versatile glass, a pair of glasses, and again, it, it becomes more of a habit of I'm gonna wear my eye protection just in everyday life.

And they're always on you. Is that kind of the thought process there? Well, sometimes we forget to throw on the side shields and sometimes we don't think it's fashionable or looks good. So in fact, again, here comes one of those things where feedback is critical, right? They, they tell us all the time, Hey, our employees are removing the side shields.

So we solved the problem, right? Our customers came back and said, Hey, we don't want that site shield being removable, but we wanna keep that style. Glasses. Uh, what I'm gonna show you here is a 3D prototype. So we added the side shield. It's fully integrated now to the temple, so it's non-removable. And of course it's gonna be clear so that it's not visible.

But those are just things that we like to do. We like to solve problems. Our, our customer's feedback is valuable. It's, it, it's what makes us better. So now that you're, how many years into this are you? I've been, it's gonna be this year's, five years. Five years. Five years. Yeah. What's been your greatest learning?

I'm sorry. Six years? Six years. Six years. Wow. Six years. What's been your greatest learning? Um, trial and error. Uh, we make a lot of mistakes. Um, the material that we choose, the lenses that we, we select, um, in fact, even the manufacturers that we select, it, it, it all, it all comes into play. And I think one of the valuable lessons is that.

When it comes to designing and engineering, do something different. Um, stand out. Uh, our last frame. You know, it was a great hit. I'll show you.

So as you're aware, you know, we work 24 7. You know, we work nights, we work gloomy days and times. You can't wear a dark lens, right? So you have to wear a clear lens. So utilities, contractors, they like to, they like to bite. Two frames, a clear lens and a dark lens. So this frame right here solves that problem.

It's a C 87 plus, as you can see, it's very fashionable. And this one, what I, what, what we did is our engineers came up with this little knob right there. You twist it and then you pull out your lens, right? You can swap it for your clear lens or your amber lens or any other color lens that you like, and that, that avoids companies paying for two frames rather than just one.

And that's what we do every time we, we, uh, come up with a new product, we make sure that we have that mentality of what if I'm at work right now and I'm doing this or I'm doing that, then we like to put that into play and we take it into consideration. Felipe growing up, were you an entrepreneur? Were you one of those kids who like was always thinking about, how do I start a business?

Mm-hmm. How do I do this or that? You know, uh, when I was young, um, I used to buy cars and sell them. I don't think that's an entrepreneurship, but I, I like to buy things and sell them and, um, I always had that in mind. So, uh, I don't know, something just clicked and it said, okay, let me, lemme start a business, but it's not as easy as 1, 2, 3, right?

It's, it gets deep. So everybody says, oh, just open up an LLC and start a business. It's, no, it's not that easy. It, it takes a lot more than that. Um, I didn't know what I was getting myself into to be a hundred percent honest with you. Uh, but, you know, six years down the road I'm learning. I'm still learning.

And, uh, yeah, it's a, it's a lot of learning lessons. I, uh. I have four businesses that I've started over the years and it, it's, it is not easy. I mean, it's, it's around the clock. What would you say to, to people who have an idea in their head? 'cause you know, you talked about working a hundred hour weeks, that's a lot of time to, to be.

Thinking about ideas Absolutely. And seeing opportunities for innovation. What, what would you, uh, say to someone who maybe is mulling around some of those ideas in their head, uh, about what, what to expect, what, what the journey is really like. Yeah. And you know what, we're starting to see that a lot more often.

A lot of guys are starting, uh, small. They come up with new tools and, uh, safety equipment. So if you're out on the field and you're dealing with, let's just say rolling that wire or. Carrying that tape around and you can say, man, I wish I had this little clip to put my tape, or, I wish I had this tool to roll up my wire.

It'll be so much easier. Just right there. You started something. And the hardest part is to actually sit down and think about a concept. Once you start that process, it, it's, the ball starts rolling, right? And, um, I, I encourage people to do it, uh, better our, our field. I think, uh, one of my favorite brands right now, it's Maddie Tools, actually, uh, Ralph and Jason have done a great job.

One of the most common tools that we use is our, our socket. It's a 9 16 3 quarters, and they're adding that to almost all the tools to the, uh, to crescent wrenches, to the goat, uh, wrench. And then it's just one of those things that says, Hey, one tool has five tools in it. So, you know, don't, don't be afraid to get out there and find a better way to do your job.

Absolutely and don't get discouraged. I've been, I've dealt with times where I'm like, I just wanna sell my company and go back to work. Man. I don't wanna do this. It's hard. It's tough. You, you come to a dead end, but it, it's part of the job. It's part of it, you know, it, it's, you just gotta find that motivation and continue pushing.

'cause there's been those times where I just want to call equipment, I'm done. But you know, it's powered through. Absolutely. Tell us about that moment where you took the first step, because I think that first step is the hardest because there's, you've got skin in the game. I mean, you're financially, you know, investing in an idea, you're, uh, putting mental, uh, you know, an emotional time into it.

What was that first step like for you? Um, it was scary. It was the scariest thing that. Uh, I've done, you know, just me and my buddy we're, we're getting drunk actually outta Buffalo Wild Wings. We were there a long time and, uh, we had been talking about opening up an LLC and trying to do some tax runoffs, and that day we, I remember we were watching football, so we got there like I wanna say, around noon at Buffalo Wild Wings, and we were there till three in the morning.

Just drinking and we were talking about the ideas and how we can do it. Finally, we, um, his wife drove us home and by the time we got home, we had already, she bought the tickets to fly out to Hong Kong and find manufacturers and. In the morning. She's like, Hey, you guys are gonna Hong Kong. And I was like, what?

She's like, yeah, I got you guys the tickets. You guys told me to buy them. And she goes, you used your credit card? And I was like, what? I was like, alright, you know what, let's do it. You know I hopped on that plane. It was a 15 hour flight I got there. I promised you I felt like a complete idiot. 'cause everybody was like dressed up.

They had nice button ups. I pulled up in a t-shirt with my jeans and a hat and I feel like I told my buddy, I was like, you know what? They were looking at us like we don't know what we're doing. Yeah, so we found a manufacturer. They did take advantage of the fact that we weren't, we were inexperienced.

But of course, after years and gaining experience, I flew back and I renegotiated, I found the manufacturers and, you know, everything starts to come in play. The pieces start falling in, in together. So it's, it's very scary, but once it starts, it's exciting. What has been the hardest part of this journey? Um, in the beginning it was probably the, the finances, right?

Um, it does take some money to, to invest. Um, I remember, like I said, I was single. I didn't have any kids. I didn't have a house, I didn't have bills. So I remember I had, I think, like $10,000 in my bank account, and I looked at my buddy. I was like, I'm gonna put it all in. I said all of it, I don't care. And that's what I did.

I put it all in. I think that was very hard for me to just dump that money, especially not knowing what I was doing or what the outcome was gonna be. You know, I just, I took a risk and it, it worked out. And of course it also falls on how much work I'm willing to put into the company. Uh, I've always said it, I'm gonna get as far as I want to.

If I stop right now, that's as far as I'm gonna get. But if I kept pushing, I'm gonna make it and I believe in myself. I believe that I'm actually gonna make it pretty far. What has come the easiest in this journey? Like just feels like a natural extension of who you are. Oh, the easiest part is that people like they love glasses.

We wear sunglasses all the time and the easiest part is just saying, Hey, this is for sale. And then say, oh, these are nice. And that's been like the easiest part. I always thought I was gonna struggle. I remember the first day we launched. I was thrown back and my c my cousin, she was at the time helping me, she's an accountant and she goes, this is how much you sold in one day.

I was like, yeah. She was like, I have never seen something like this before. And it was amazing. It was like, guys were supporting us, guys love the product. And I got a lot of feedback on the logo, of course. Um, and one of the things that I'm gonna stick around with is this industry. I don't think, uh, I want to focus anywhere else but this industry.

And that's our goal here. How have you built brand loyalty? That, that's definitely something that takes a lot of effort and intention by taking customers' feedback seriously. Uh, I'm pretty sure you've dealt with angry customers, upset customers, and, um, it can be hurtful. You know, they, oh, your glasses are cramp, blah, blah, blah.

And it's just that one defective product. And, you know, we are humans. We make mistakes. People that put together our product make mistakes. Um. A few times they've had our logos upside down and it's like, uh, customers, oh, you guys don't even put pride in the work that you did. I'm like, it's one out of.

5,000 units. And it's one of those things that, okay man, don't worry. We, we got your bag. We'll replace your product and we'll give you a free hat or free stickers. And it's not so much that you know, that that hat means a lot to them. It's like, oh, they like us. They take, they took care of us. And that's what we're doing continuously.

It's, it's worked for us. It gives us a lot of, uh, customer returns and keeps that loyalty. Keeps that loyalty around for sure. One of the hardest. Parts of entrepreneurship is knowing when to cut the cord and meaning, you know, you're still working as a groundman, you have WYE Delta on the side, and it's like you're dealing with back injuries.

And then you, you have to make that decision of like, okay, once again, I'm all in, I'm, I'm gonna step away from, uh, you know, stable job, stable income, and I'm gonna put it all into, into this project. Walk us through that decision. Yeah. So, um, I remember I was working those fires in Los Angeles that just happened last year.

Um, and I was working seven sixteens, and I remember I had no time for my customers. I lost a lot of business. I lost a lot of clients. And at, at my, my company was doing just enough. So I, I, I spoke with my wife and I said, my wife's a nurse. And I said, you know what, uh, WYE Delta is sustaining us. If you quit your job, I'll quit mine.

You, you help me with the kids, help me around the house, um, and take care of customer service while I do everything else. And me and her, I work, I think it was like three consecutive weeks and that money was enough to sustain and for me to push. And I told my wife instead of working. 16 hours a day for someone.

How about I work 16 hours a day for myself, and we, you know, we, we made a plan. We, we, um, executed it and it worked out. And right now I have time to, to talk to my customers, follow up at work. I'd get calls and I'd be like, my boss not around. Let me take this call. Hey, can I call you back? Sure. And I couldn't call them back because I'm working the rest of the day.

And it's just one of those things where I had to make that decision. What's more important, my business or my job? Don't get me wrong. Working for utility has been one of the greatest things that happened to me. Money's good. Benefits are good. Um, that was one of the biggest, uh, uh, questions as well. It was now I have to pay for benefits.

You know, as soon as I quit, I was paying $1,700 a month for insurances and it's like, all right, let's do this. We powered through, let's work, you know, and, and we made it happen. My wife and I worked together as a team and, um, everything worked out. What advice would you give to someone who has an idea and they potentially wanna bring it to market, or they want to explore that further?

What would, what would you tell them in terms of like where to start and what to expect on that journey? So when I first started, I reached out to a lot of companies, uh, a lot of linemen or lineman owned companies that were already out there. They were pretty big, pretty popular in the industry. And at times they would je i I reach out like, Hey, how you doing?

My name is Felipe. I'm trying to join, uh, the industry that you're in. Um, I'm starting a safety sunglasses. Can, can you help me? Can you guide me? And a lot of the times I got rejected. They said, no, man, you just gotta figure out on your own. You got this. And I said, all right. You know. So for someone that's out there and wants to start something or you already started, I, I will reach back to you.

If you contact me on social media, they'll direct you to my email and you can contact me. And I am willing to put 20, 30 minutes aside to guide you in the direction because there's nothing better to have people follow your footsteps. Right. And uh, there was, again, there was this company, and I'll never forget what this guy told me.

He's like, he's like, I don't got time for you, man. Just figure it out on your own. I was like, man, what a, you know, this, this guy's an owner. And I, and I get it, you know, he is busy. I'm busy now, but I'm always willing to help people out. So if you call me or if you email me and say, Hey, Felipe, you know, I'm starting a new product.

Where do I start? How can you help me guide? I'll, I'll definitely put some time aside and, and help you guys out a hundred percent. Because I remember being in those, in, in that spot where I constantly got rejected by companies that were higher up and they didn't want to deal with someone that was just starting off.

You mentioned that you want to stay in the electric trades just because, uh, that's where you started. What, what about the electric trades, um, has created that loyalty? I've made a lot of friends, a lot of linemen, a lot of groundman, a lot of apprentices, a lot of safety coordinators. I've made a lot of friends.

Most of my customers, I treat 'em like friends. And because we're, we can relate to the work and field. Uh, experiences and knowledge. Uh, it, it, it goes hand in hand. So, uh, there's a lot of alignment out there that represent my product. There's alignment, a lot of alignment that are doing videos. Every day we're in our product.

And it's just, I don't wanna leave that behind. You know? I don't wanna be like, okay, you do that and I'm gonna move on. I'm, I wanna just how they're loyal to me. I wanna stay loyal to them. And the only way that, that, that works is loyalty. Right? So, and it's also mutual respect. These guys are amazing. They, they talk so good about my product and they help me out a lot.

So I don't wanna leave them behind if, you know, if I'm going somewhere, I'm taking them with, with me, for sure. I, I, I just, that's. I know becoming rich is always a goal for people, and I want to be that person, but. I wanna bring as many people as I can with me, you know, especially the ones that were there from day one.

What would you advice would you give to someone about the way that the world is going in terms of building a brand? And especially if you do want to go down the path of being an entrepreneur, the importance of leveraging social media to, to build your audience and to build your brand. Yeah, so I'm a little camera shy.

If you go on my social media, you won't see me very much. I'm, I'm there, but not a lot. Uh, but I've seen successful stories of people that post videos every day of themselves, um, doing like a selfie video and talking about, uh, the impact that they wanna make in their industries. And I, I feel like I need to do that, but I just, I don't feel like I have.

I don't know. It's just not in me. You know, I'm a little camera shy, but I feel like if I were to record myself constantly and make videos about the trade, about the industry, about improvements, about the importance of safety, I think I would definitely gain more followers. Uh, so if I was to give an advice, if you have it in, you do it because I don't have it in me, and I, I wish I did.

It's just one of those things that will help you a lot on social media, especially given the face to the company. Are there any final thoughts that you'd like to leave the audience with? Don't wait for something to happen. Uh, wear your proper PPE. I've seen it happen. Uh, we've seen stories of people, uh, wearing the proper PPE and people not wearing proper PPE, whether it's our brand or someone else's.

It is important. If you've been in the field for 20 years and you've never experienced an incident, don't get comfortable because it could be 20 years in one day when it. All, all of a sudden it happens. Um, I, for 1:00 AM guilty of wearing Oakley Holbrooks in the field until I saw someone get injured and get an impact to the face.

That's when I said, okay, I gotta take my stuff serious. Uh, stretching. You know, your body is very important. You don't feel it now. Down the line, you will, I'm only 33 and I'm already feeling it. So at 40 I can only imagine how much pain you know you're gonna get. And you're gonna remember, you're gonna say, man, I wish I could go back.

You know, so make sure you just take that seriously. Do your, make sure you stretch, make sure you drink enough water, stay hydrated. Um, and yeah, just don't wait for it to happen, for you to take it serious. Along those lines, why do you think it's important that people in the trades see themselves as athletes and, and do the things that an athlete would do to take care of their mental, physical, uh, body so that they can have that career longevity?

Absolutely. So keep, think about it. Uh, your body is your money maker. If, if you get injured, if you. Something if a hand, if you cut yourself because you weren't wearing the proper PPE for the rest of your life, you're gonna carry on and you're gonna have that guilt. You're gonna tell yourself and ask yourself, why didn't I do it?

I could have just been wearing my glasses. I could have just been wearing my hard hat, my gloves. Um, you're without your body. You're not making money and without making money, you're gonna struggle with bills, you're gonna struggle with sources of income. I recommend that you truly take care of yourself and, uh, your body is very important.

So, you know, nutrition, um, exercises, um, what, what your stretches and. Properly protecting yourself. Again, it doesn't have to be WYE Delta for you to be protected from your eyes. You can wear any other brand. Just wear something safe. Felipe, thank you so much for sharing your journey from the job site to the founder's chair.

Uh, and I will say your story highlights how frontline experience combined with curiosity, grit, and a commitment to the quality, uh, that people want, can create something that genuinely serves people doing the frontline work. Uh, and it's also a reminder that innovation often starts with. A question rooted in lived reality, and you did such a good job of, of just tying your entrepreneurial journey back with that lived experience and saw a gap in the market.

And it was pretty cool to walk through that. So what I'd like to leave everyone with is that if this conversation challenged how you think about work injury prevention, what it really takes to last in the trades, make sure to follow, uh, the WorkRready podcast on your favorite platform and subscribe.

Share this episode with someone who cares about doing this work for the long haul. We're continuing this conversation inside the Vimocity WorkReady Community where Felipe is gonna join us for an extended discussion on what it truly means to be work ready. Thinking like an industrial athlete, investing in your health and your durability and making decisions today that protect your career years down the road.

We'll also explore how injuries change perspective, how to spot warning signs early and how leaders can model long-term thinking over that. Just grind it out. Culture membership is free to the work ready community, uh, through animosity and so you can check out the show notes for additional details.

Thanks for spending your time with us. Take care of yourself. Take care of your people and stay work ready.

Discover how Vimocity can help keep your crews WorkReady.

One comprehensive platform to help safety and operational leaders prevent more injuries and incidents.